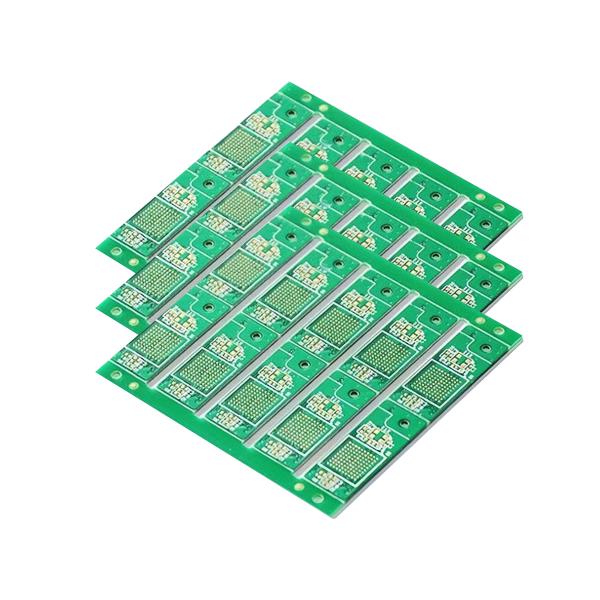

Name | Printed Circuit Board Fabrication | Reinforcement type | PI, FR4, steel sheet, 3M glue, the electromagnetic shielding film |

Insulation | FR4 board, aluminum substrate, copper substrate, a ceramic

substrate, PI (polycumimine), PET (poly) | Maximum size | 50OMM*1000MM |

Copper foil material | Glue-free calendered copper, rubber-rolled copper, glue-based

electrolytic copper | Outer line width/line spacing | 0.065MM( 3MIL) |

number | 1-12 floors | Inner line width/line spacing | 0.065MM(3MIL) |

The finished board is thick | 0.07MM AND ABOVE (TOLERANCE +5%) | Minimum solder mask width | 0.10MM |

The inner layer is thick copper | 18-7OUM (1 ounce copper = 35UM) | Minimum mask bridge width | 0.05MM |

The outer layer is thick copper | 20-14OUM (1 plate copper = 35UM) | Minimum solder mask | 0.45MM |

Solder mask | Red oil, green oil, butter, blue oil, white oil, black oil, matte

black oil, yellow film covered white film, black film | Minimum aperture | MECHANICAL DRILLING 0.2MM, LASER DRILLING 0,1MM |

word | Red, green, yellow, blue, white, black silver | Impedance Tolerance | 10% of soil |

Surface treatment | Anti-oxidation (OSP), tin spraying, gold immersion, gold plating,

silver plating nickel plating, gold plating finger, carbon oil | Form tolerances | +0.05MM(LASER+0.005MM) |

Special processes | Thick copper plate, impedance plate, high-frequency plate,

half-hole plate, orifice plate, hollow plate, single-layer copper

foil, cross-sided gold finger plate, soft and hard combination | Molding method | V-cut, CNC, die punching, laser |